Tooling profile change

For punches

Modifications of the tool parametersModifications of the tool parametersModifications of the tool parameters

|

Modifications of the tool parametersdue to "throughhardened" quality, Amada tools doesn't need to be heat treated after a modification

|

|

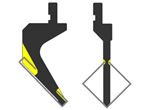

Modifications according to the shape of the sheet metal partdue to highest strenght of the body, Amada tools can be modified much thinner than conventional tools

|

|

Modifications of the ear tool (length and profile) |

|

Modifications of the punch body for closed bending |

|

Rulers with special radii |

For dies and holders

|

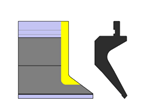

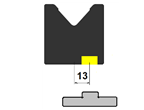

Modifications of the tool parameters

|

|

Modifications according to the shape of the sheet metal partdue to highest strenght of the body, Amada tools can be modified much thinner than conventional tools. AFH and OneStroke dies are already offering a maximum of "freedom around the tool". |

|

Modifications on the holder side of the die

|

|

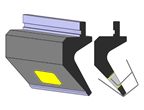

Modifications on the die holder (height, length) |