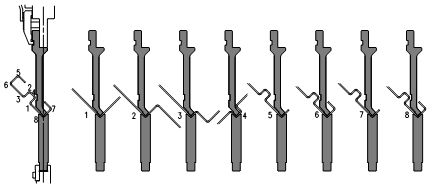

Special solutions

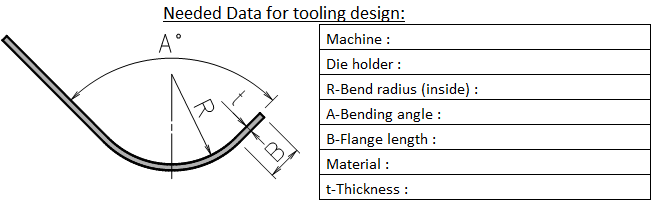

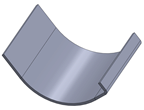

Radius bending (using air-bending tools)

|

Considerations:

|

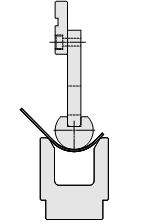

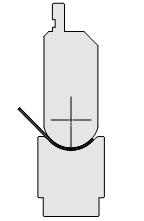

Radien bending (using counterpressure)

|

Considerations:

|

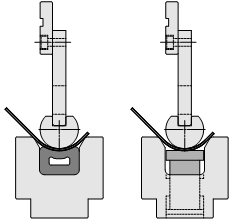

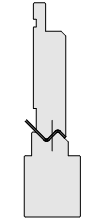

Radius bending (using coining tools)

|

Considerations:

|

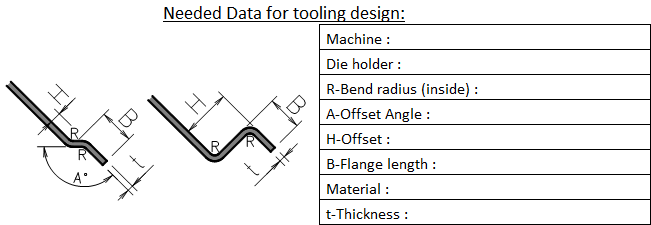

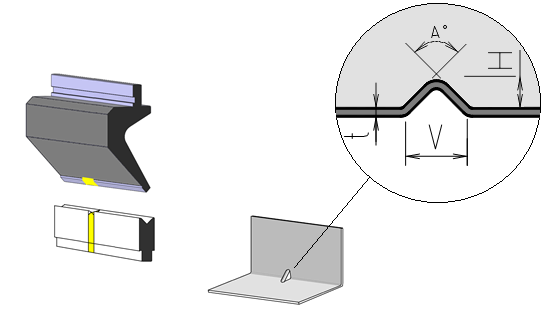

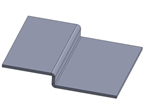

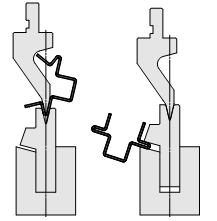

Offset bending

|

Considerations:

|

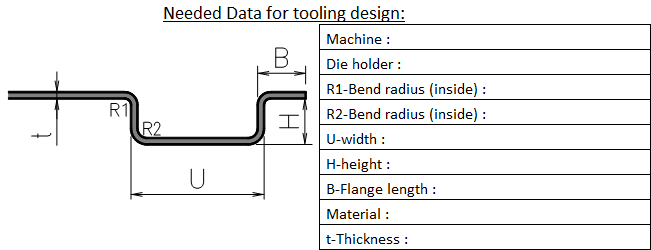

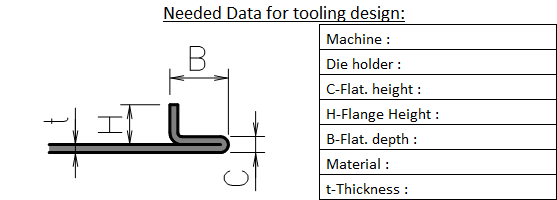

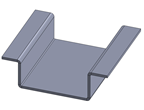

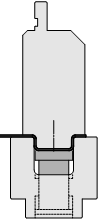

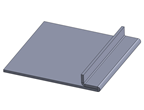

Hat bending

|

Considerations:

|

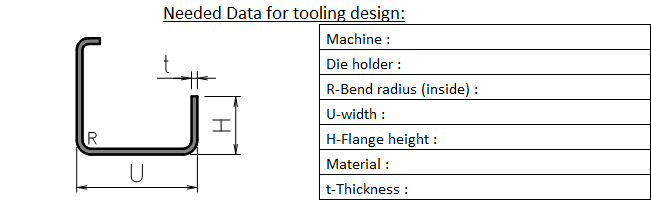

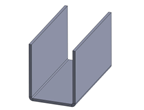

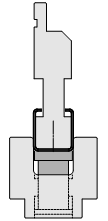

U bending

|

Considerations:

|

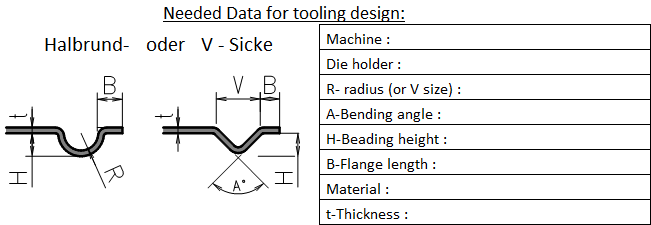

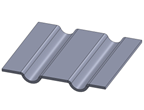

Beading (longitudinal to the bending line)

|

Considerations:

|

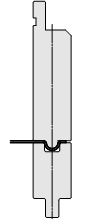

Flattening

|

Considerations:

|